POWER MASTER

Especificaciones

pm-capstan-2

pm-capstan-2  pm-capstan-3

pm-capstan-3  pm-capstan-4

pm-capstan-4

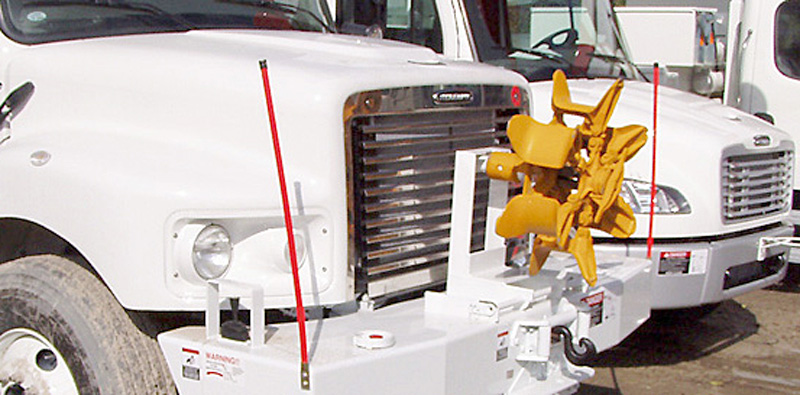

The Ramsey Winch POWERMASTERTM Series is tailored specifically for the Utility Industry. The POWERMASTER series includes a complete bumper system featuring a 20,000 lb. Hydraulic Planetary Winch with optional extended shaft. The POWERMASTER high efficiency planetary gear 6,000 lb. Capstan drive features a high torque hydraulic motor with dual counterbalance valves for smooth operation. Light weight aluminum or ductile iron 7"bayonet style Capstan heads and a stand-alone 20,000 lb. Hydraulic Planetary Winch are also available in the durable, powerful POWERMASTER Series.

The POWERMASTER Bumper offers the ultimate design in utility bumper winch assemblies. Made in the USA in our state of the art manufacturing facility in Tulsa, Oklahoma, our bumper shell is made from the highest quality galvanneal steel. Each bumper is precision welded for added strength. Welded seams and top plates lower maintenance costs by eliminating bolted connections that can come loose.

The POWERMASTER series is designed to deliver in a lighter weight, compact package that means more workload and less wear and tear. The utility bumper has a modern, contoured design to better fit and complement today's work trucks and vehicles. Available with an optional durable coating to create a stable work surface and locking latches for bumper compartments to provide added security for tools and equipment.

FEATURES

- See POWERMASTER Capstan Drive

APPLICATIONS

- General Industrial

- Specialty Vehicle

- Utility

SPECIFICATIONS

Rated line pull and line speed is based on the first layer of cable.

| Output Shaft | AT&T |

WARNING

Winches, capstans and hoists are not intended to be used for lifting or moving of persons.

CAUTION

The last 5 wraps of cable must be left on the drum to assist the cable clamp in holding the load.